The Oliver Machine Company

Muscle machines from 1903 to 1999

by Alan Lacer

|

| |

|

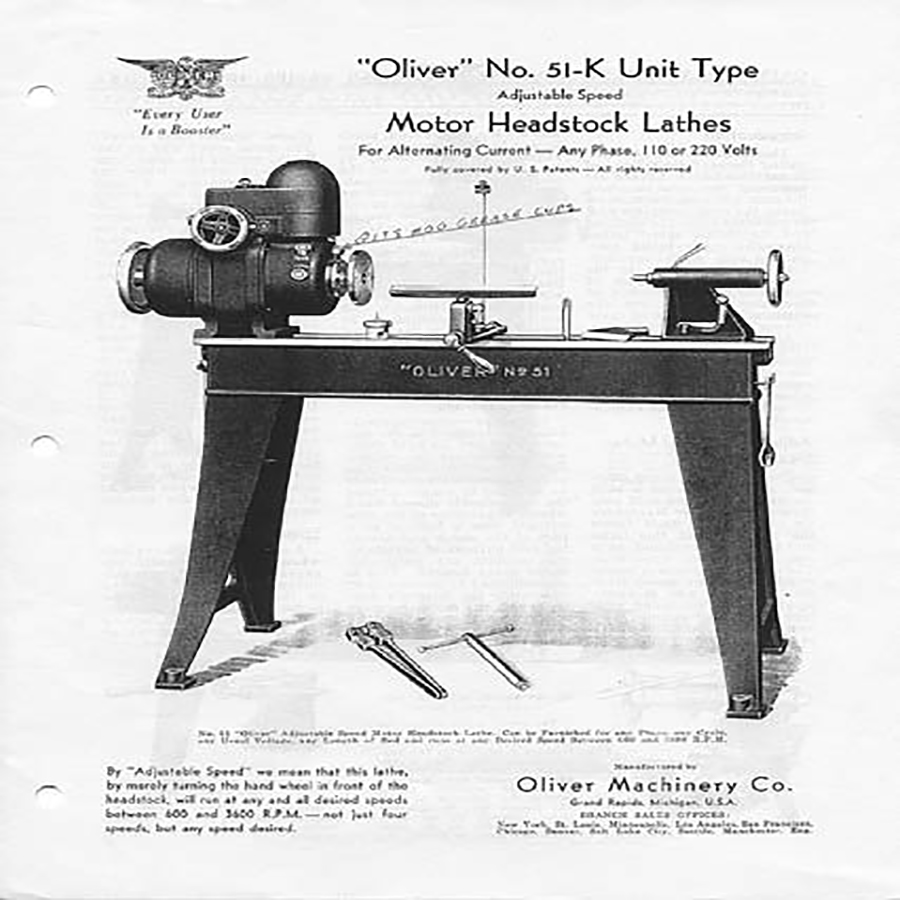

Thinking that variable speed was a recent lathe innovation? If you leaf through history, you’ll find a 1920s Oliver ad for the model 51-K that included this feature.

|

Are you looking for a lathe with a little more oomph than your midi lathe? Maybe the 62-foot Oliver 18-A pictured above would fill the bill. Or perhaps you could drop a towering Oliver faceplate lathe—capable of 100"-diameter work—into your basement shop before turning your next bowl.

If you remember life before personal computers and VCRs, perhaps you even turned at an Oliver lathe in your high school shop. The familiar Oliver logo was once the dominant player in millwork shops, trade schools, and industrial technology shops across the U.S.

So reliable were its products that it was said that the biggest problem the Oliver sales force faced was selling a second Oliver machine: Oliver tools just kept running. In fact, George Paes, an Oliver district salesman and AAW member, remembers a light- hearted offer: A bonus awaited him if he could find a paint that would dissolve an Oliver machine after 20 years of service.

Consider these industry- leading features from Oliver:

-

Gargantuan lathes weighing up to a rock-steady 5 tons (Model 22AC)

- A telescoping bed lathe (Model 26AC) that slid from 81/2 feet between centers when closed, and opened up to 16 feet

- An 8"-portable lathe, a forerunner to today’s popular small lathes

- Premium Timken tapered roller bearings

- In 1904, introduction of an electronic four-speed lathe

- Mechanical variable speed changes with pulley diameters (introduced before 1920)

- Infinitely variable AC system that allowed any speed between 600 and 3600 rpm, available in the 1920s.

Midwest roots

Oliver Company had a storied history in Grand Rapids, MI. Its roots go back to 1890 when Joe Oliver started making miter trimmers under the American Machinery Co. name. In 1903, the name was changed to “Oliver” to avoid confusion with the American Wood Working Machinery Co. of Rochester, NY.

In its heyday, Oliver produced diverse products including electric glue pots, planer/jointer knives and safety heads (to replace the square heads that were the norm), shapers, tablesaws, jointers, tenoners, mortisers, sanders, jig saws, grinders, handscrew clamps, and vises. The Oliver catalog listed metal lathes, metal spinning lathes, and of course, wood lathes of all types.

By 1994, the company estimated it had produced over 150,000 machines, with at least half that number still in use on a weekly basis. At one time Oliver had branch offices in New York City, Chicago, St. Louis, Los Angeles, San Francisco, Seattle, Salt Lake City, Denver, and Phoenix. Overseas offices included Manchester, England, and Paris, France.

This company and its products were not just aimed at standard or low-tech operations. It once designed and built a computer- controlled wood lathe to turn large patterns for missile nose cones. Oliver even designed and delivered a specialty bandsaw to cut the unique tiles for the Space Shuttle program.

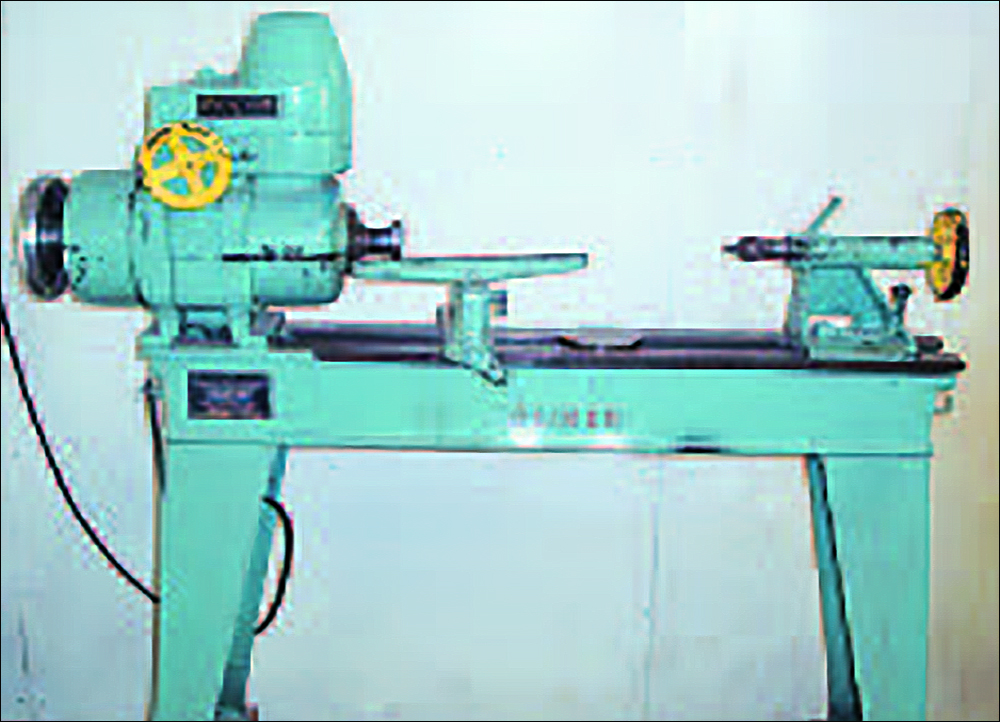

Lathes of every size imaginable were a story unto themselves. I have found no company anywhere in the world that made such a diverse range of lathes, from their small “Junior Lathe” to enormous faceplate lathes and the beast shown above.

Pattern and millwork shops and especially public and trade schools were commonly outfitted with Oliver lathes—known for their ruggedness, heft, and reliability. Innovations included direct power drive lathes (the headstock spindle is the armature for the motor), electronic variable speed systems, and motor or spindle brakes to reduce the time to stop the machine. Oliver also pioneered quick-action tailstocks, chucks to hold square material, and an improved system for locking tool rest bases.

And today? The company we revered ended in 1999 when an individual purchased the Oliver name. You may see woodworking machinery (tablesaws, shapers, jointer, sanders, but no lathes yet) made in the Orient under the Oliver logo. However, these Asian machines aren’t original Oliver designs at this time.

A former employee, Richard Fink, purchased all Oliver drawings, patterns, documents, machine inventory, and many parts to service the Oliver equipment still in service. Under the Eagle brand name, Richard now manufactures two original Oliver machines—the 24" planer and the famous Straitoplaner that mills coveted.

References: Vintage Woodworking Machinery by Dana Batory. Special thanks to Richard Fink of Eagle Machinery and Repair (Oliver Machinery employee from 1976 until 1999 and the source for Oliver parts and service), and to George Paes of Nipomo, CA, a former Oliver employee district salesman, for their assistance in researching this article.