What is wood grain?

Grain most commonly refers to the texture and appearance of the fibers that make up the wood. When you saw or split a piece of wood, you cut through the tree’s annual growth rings, exposing a pattern of alternating light and dark areas. Together, those areas comprise the grain.

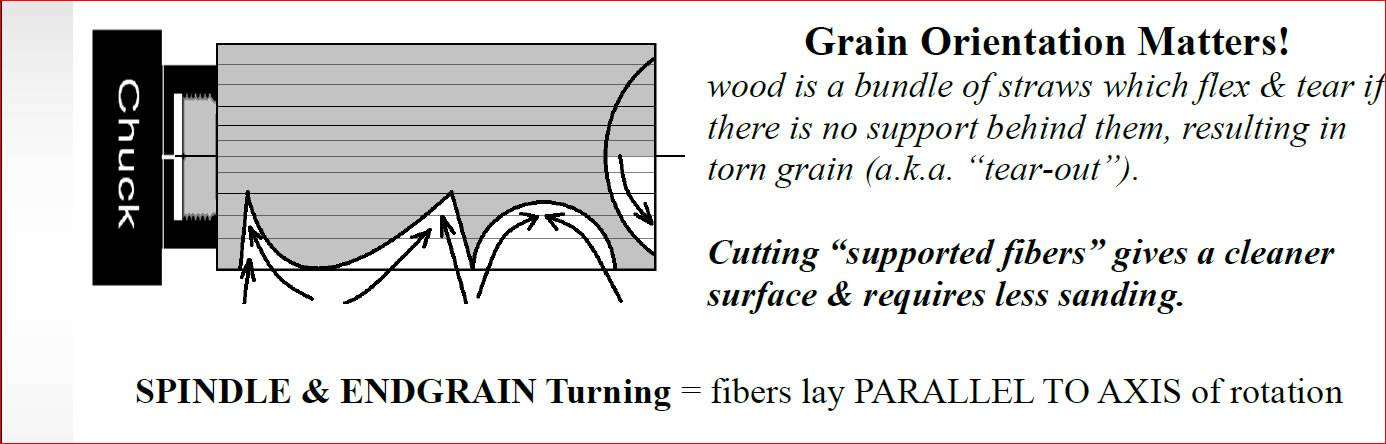

The cellular structure of wood is like a huge bundle of tiny straws. Wood termed fine-grained has relatively small-diameter cells or inconspicuous growth rings that result from slow growth. Boxwood is one example of fine-grained wood. On the other hand, coarse-grained wood has relatively large cells or wide, conspicuous growth rings. Ash and oak are just two examples.

How does grain affect our woodturning?

Figure courtesy of Eric Lofstrom.

The biggest impact of grain is the direction of the cuts you take. You get your best results when you cut with the grain, not against it. You’re slicing those long wood cells along their length, not chopping across their ends.

In spindle turning, where the grain runs parallel to the lathe bed, most of the cuts follow the direction of the grain. Cuts to form beads and coves, which curve toward the center of the wood, slice through the endgrain at an angle.

In faceplate or sidegrain turning, where the grain runs perpendicular to the lathe bed, each revolution of the lathe presents endgrain and sidegrain wood to the cutting tool. Endgrain wood is much harder than sidegrain, and the fibers can easily be torn instead of cut cleanly.

Grain also affects how the wood absorbs finish. Endgrain (the ends of those straws) sucks in finish more readily than sidegrain. Occasionally woodturners have a requirement to glue wood together. Grain orientation greatly affects the strength of a glue joint. Sidegrain-to-sidegrain joints are generally the strongest.

So wood grain affects our choice of wood for a turning project, our tool choice, our cutting techniques, our finishing techniques and more.